When buying castors, it can be tempting to focus purely on price. On paper, cheaper castor wheels may look like a quick win for the budget. But in reality, the wrong castors can cost far more than they save.

Whether you run a warehouse, workshop, retail shop or production facility, mobility plays a crucial role in day-to-day efficiency. Trolleys, racks, workstations and equipment all rely on castors to keep things moving. If those castors fail, everything slows down. That is where real costs start to add up for your businessLet’s take a closer look at how choosing the right castors from the start can save you money and keep your business flowing.

The Hidden Cost of Cheap Castors

Low-cost castors often use cheap materials, weak brackets and low-grade bearings. They may cope for a short period under light use, but in busy working environments they quickly begin to show their weaknesses, especially with heavy loads or demanding use.

Common issues include:

• Flat spots forming on wheels

• Bearings wearing out prematurely

• Brackets bending under load

• Brake mechanisms failing

When a castor fails, the expense is not just the price of a replacement wheel. There is labour time to remove and refit it. There may be damage to the equipment it was attached to. And in many cases, operations have to stop until the replacement comes which can prevent many staff members from completing orders – resulting in hundreds of pounds being lost.

If a trolley breaks down during peak logistic hours, or a mobile workbench becomes unstable mid-task, the knock-on effect can be significant. Delays cost money. Missed deadlines cost money. Lost productivity costs you lots of money.

Suddenly, the “cheaper” castors, don’t seem like much of a saving,

Downtime Is the Real Expense

In most commercial environments, downtime is far more costly than quality components. A broken castor might delay goods being moved across a warehouse. The packaging team then get stalled and remain idle until it’s back.

By investing in high-quality industrial castors, you reduce the risk of unexpected failure. Stronger brackets, bearings and durable wheel material designed to cope with constant use and heavier loads.

The result is simple - fewer breakdowns, less disruption and greater reliability across your operation.

Matching the Castor to the Application

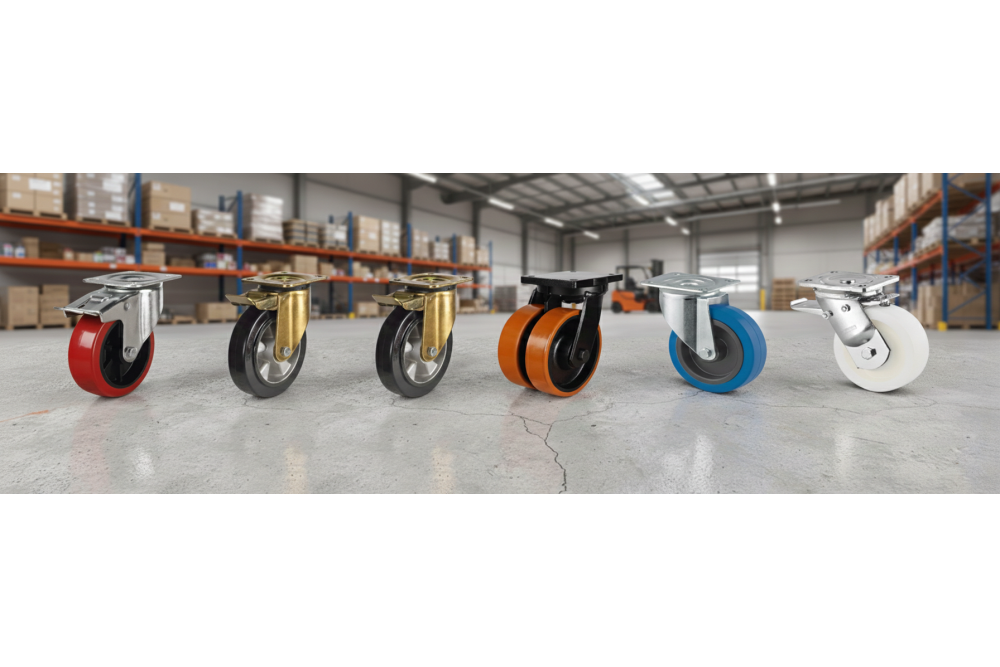

One of the biggest money-saving decisions you can make is choosing the correct specification of castors from the start. Not all castors are built for the same job unlike most people seem to think… “They are all just the same”.

For heavier loads, robust heavy duty castors provide reinforced brackets and higher load capacities. Using a light-duty wheel in a demanding environment is a false economy and will almost always lead to early failure.

Wheel material also matters.

For example:

• Polyurethane wheels offer excellent wear resistance and protect floors.

• Rubber wheels provide shock absorption and quieter movement.

• Nylon wheels handle high loads and resist many chemicals.

Selecting the correct wheel for your floor type, load weight and working conditions improves longevity and reduces wear on both the castor and the surface beneath it.

It is not about buying the most expensive option. It is about buying the right one.

Reduced Maintenance and Replacement Costs

Frequent castor replacements create a cycle of ongoing expense. Even if each individual wheel is inexpensive, replacing them every few months quickly becomes costly.

Quality castors are designed for durability. Higher-grade bearings reduce friction and wear. Thicker steel brackets resist distortion. Properly rated load capacities prevent overstressing.

Over time, this means:

• Fewer replacements

• Lower maintenance time

• Less stockholding of spare parts

• Reduced call-outs for repairs

When viewed across a year or more, the total cost of ownership is often far lower with a premium castor than with repeated purchases of cheaper alternatives.

Protecting Floors and Equipment

Another overlooked cost is floor damage. Inferior wheels can break and develop sharp edges that mark and wreck surfaces. Repairing damaged resin, vinyl or concrete flooring is often much more expensive than upgrading your castors in the first place.

Similarly, failing castors can cause equipment to tip or become misaligned. This risks damaging valuable machinery or stock, or, worse, injuring your staff.

High-quality castors allow smooth rolling, distribute weight evenly and maintain structural support. That protects not only the wheel itself but also everything it supports.

The Smart Way to Save

Saving money with castors is not about choosing the cheapest option available. It is about investing wisely in quality, specification and reliability.

Well-chosen castors keep your business moving, no matter the demand. They reduce downtime, lower maintenance costs, protect your property, and improve the safety & conditions of your staff. In short, they support productivity, rather than becoming a burden.

If you are unsure which castors are right for your industry, it is always worth seeking advice before purchasing. Perhaps one of our previous blogs cover it – or, you can contact the team here.

Get Things Moving!